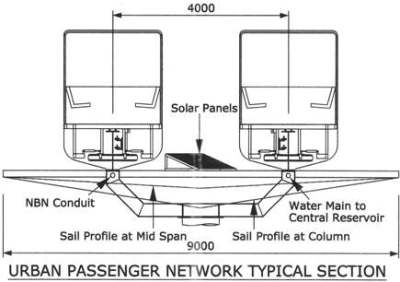

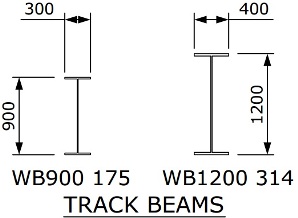

Track Construction:-

The track concept is based on the use of 900WB 175 welded beams for urban tracks and 1200WB 314 for rural

tracks. These are commercially available beams manufactured using steel plates and a continuous welding machine.

They will be fabricated in a specially built factory in a suitable location for each network.

After fabrication, they will be transported along the newly constructed MonoCab VRT track for erection. This

will significantly reduce construction costs and disruption to traffic.

These beams are commercially available.

The WB900 175 beam weighs 175 kg/m and will be used in the urban tracks. Current retail cost is $426.00/m.

The WB1200 314 beam weighs 314 kg/m and will be used in rural tracks and tracks that will carry freight.

Current retail cost is $846.00/m.

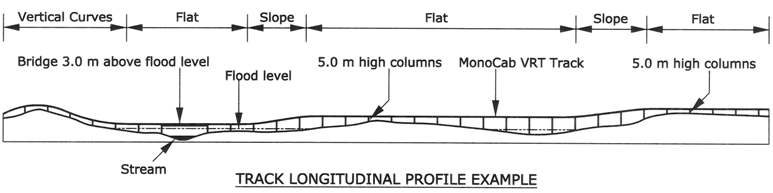

The tracks will ALWAYS be constructed above flood level as shown below. Note how the heights of the

columns vary to achieve the best, most comfortable track alignment and keep the track above flood level.

Snow falls will not interrupt service. The 400 mm wide top flange is over 6.0 metres above

ground. The cars will disperse the snow as they pass.

Arterial Roads:-

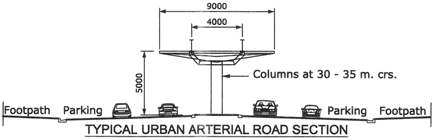

The columns will be 900-1200 mm diameter steel erected on suitable foundations at approximately 30 metre (100

feet) centres in the medians as shown on the right.

As a general rule there are few services in the medians, hence minimal changes to existing infrastructure will

be required with the resultant cost and time benefits.

Overhead power lines and street lights will normally be the only services effected. The minimum clearance under

the track will be 5.0 metres with a minimum of 6.0 metres at existing intersections to guard against impact from

high loads.

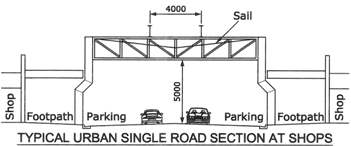

Roads with No Medians:-

Where there is no median, the track can be erected as shown on the left where it passes through an existing

shopping precinct.

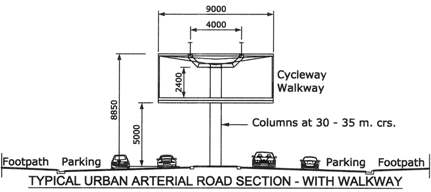

Arterial Road with Optional Walkway:-

By raising the tracks, a walkway/cycleway can be suspended underneath.

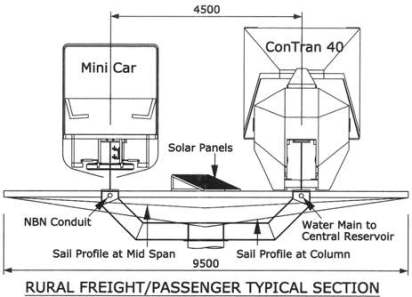

Rural Tracks:-

This configuration is similar to the urban track but has larger rails to cater for the heavier loads of freight

transport. The rails are also further apart to reduce buffeting when two vehicles pass each other going in the

opposite direction. The effective closing speed is 400 km/h (200 km/h each way).

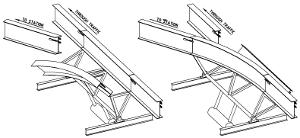

Points:- Points:-

At each station/stop, this points system allows a car to be taken off the main line and not impede through

traffic. Cars either side of the car stopping will have their speed varied to allow sufficient time for this

operation. As a general rule, it will only be at these locations that any land acquisition/resumption may be

required for car parking with cost and time benefits.

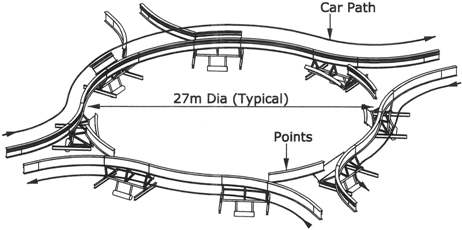

Urban Intersections:-

This is the configuration of a typical track intersection. It uses a slightly modified version of the points

above to divert vehicles onto other tracks.

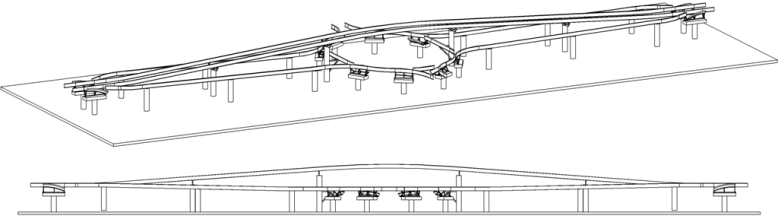

Rural Intersections:-

In locations where there is significantly higher traffic in one direction, the track configuration would be as

below. The most usual location would be on a highway but may also be utilised on highly trafficked arterial

roads. This allows the traffic on the main MonoCab “highway” to pass this intersection without interruption

and reducing speed.

Computer Integrated Manufacturing:-

The manufacture of the tracks will be enhanced by the adoption the "CIM Steel" system (Computer Integrated

Manufacturing) that has been recently developed and adopted in Europe. In this process, the geometry of the steel

is developed and structurally analysed in the engineer's office. The final design data is then transmitted

electronically directly to the fabrication shop for fast, computerised, "just in time" manufacture and immediate

delivery to the site. This process will give significant time and cost benefits.

|