|

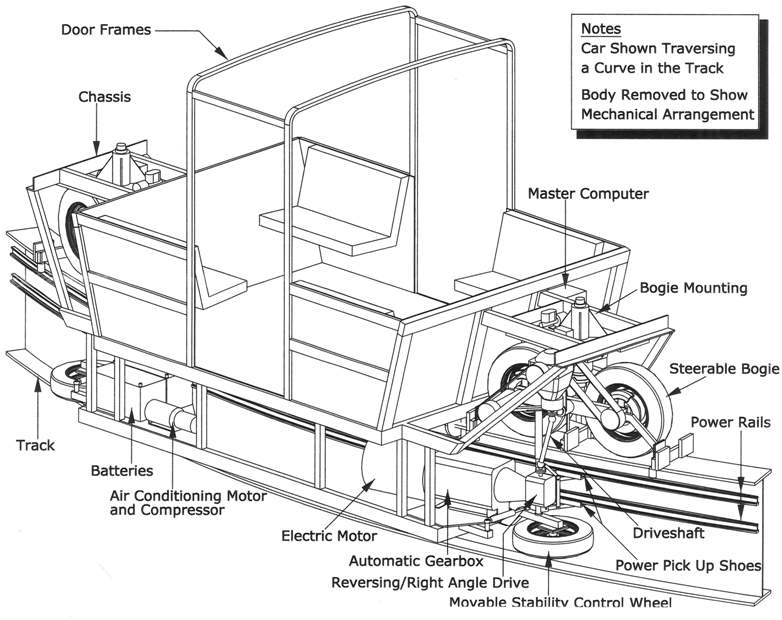

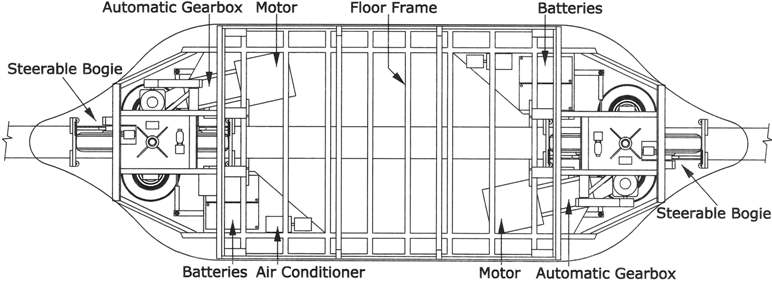

Passenger Cars:-Mini and Maxi Car Chassis:-

The cars will have fibreglass or plastic body panels fitted to a fabricated steel chassis. The weight for the Mini car is estimated to be approximately one tonne. The Maxi car would be approximately 25% heavier. The cars will be able to travel in either direction. Drive Train:-

There will be two drive trains in each car. Both will be used to accelerate the car from rest but only one will be used when the car reaches it's programmed transit speed. The use of two drive trains insures against the risk of any failure.

The wheels will be standard automotive wheels and hubs (eg Commodore/Falcon) fitted to a specially designed drive train. This ensures that the car can traverse any slope that an ordinary car can e.g. a basement ramp (1 in 6). The cars will be powered by electric motors driving through a standard automatic gearbox (eg Commodore/Falcon). This gearbox will allow the motor to operate at the lowest possible RPM giving benefits in reduced maintenance, reduced energy consumption and reduced motor costs due to the lower RPM duty requirements. The cars will be quiet in operation due to the rubber tyres and electric power.

The drive train will incorporate a generator to provide regenerative braking to charge on board batteries. These batteries will provide the power to operate the lighting, air conditioning, computers etc on the car plus emergency power in the event of a blackout. The drive train will be in modular units for quick and easy replacement for maintenance. Both the Mini and Maxi cars will accommodate a 10 metre radius turn. This is the minimum design road radius for a car travelling at 50km/h. This minimum track radius will fit in a typical suburban street and, hence, permits greater design freedom for the track layout. The larger Express (30 seats) and Commuter (60 seats) cars follow the same design philosophy but use components from the trucking Industry.

The design of the cars will incorporate off the shelf components to the greatest possible extent. After all, we don't need to re-invent the wheel (others do). This design philosophy will reduce the cost of the cars to the minimum possible.

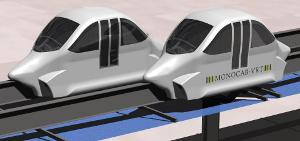

Car Maintenance:-Each car will be fitted with an array of sensors constantly monitoring tyre pressures, oil temperatures, gearbox functions etc. Any change from the normal operating parameters will initiate a warning to a central control room where appropriate measures will be taken (e.g sending the car to a maintenance centre) thus ensuring a high safety standard. It should be noted that monorails enjoy a very high safety record. Cars will also be sent automatically on a programmed basis to maintenance centres for preventative maintenance and cleaning. Car Costs:-A base model Commodore or Falcon can be purchased for about $35,000.00. These vehicles are a lot more sophisticated in mechanical specification, accessories, trim and paint options than will be required for a MonoCab VRT car. On this basis, it is estimated that a mass produced, single specification MonoCab VRT Mini car will cost $20,000.00 and a Maxi car, $25,000.00. Passenger Comfort:-Everybody likes to feel comfortable and safe in their environment. These are a couple of the reasons people prefer not to use public transport. Other reasons include lack of privacy and intimacy, noise, safety and health concerns, particularly in the flu season. A MonoCab VRT Mini car,

due it's size, comfort and speed will feel very much like their own car and,

consequently, addresses these concerns. |

|

During public displays of our MonoCab VRT model, we conduct a written survey (name, address and comments). We

also ask respondents two questions:- The Response:- |